What Type of Goods Includes Raw Materials Used to Produce Otherã¢â‚¬â€¹ Products?

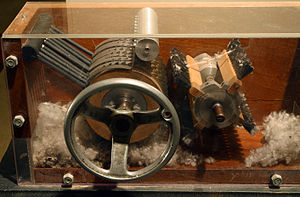

A cotton gin—pregnant "cotton fiber engine"—is a machine that quickly and easily separates cotton wool fibers from their seeds, enabling much greater productivity than manual cotton separation.[1] The fibers are then processed into various cotton fiber appurtenances such as calico, while whatsoever undamaged cotton wool is used largely for textiles like wear. The separated seeds may be used to abound more cotton or to produce cottonseed oil.

Handheld roller gins had been used in the Indian subcontinent since at primeval Advertisement 500 and and then in other regions.[ii] The Indian worm-gear roller gin, invented sometime around the 16th century,[3] has, co-ordinate to Lakwete, remained virtually unchanged up to the present time. A modern mechanical cotton gin was created by American inventor Eli Whitney in 1793 and patented in 1794.

Whitney'south gin used a combination of a wire screen and small wire hooks to pull the cotton fiber through, while brushes continuously removed the loose cotton lint to prevent jams. Information technology revolutionized the cotton manufacture in the United States, but too led to the growth of slavery in the American South. Whitney'southward gin made cotton farming more profitable, so plantation owners expanded their plantations and used more slaves to pick the cotton fiber. Whitney never invented a machine to harvest cotton, it even so had to exist picked by mitt. The invention has thus been identified as an inadvertent contributing factor to the outbreak of the American Civil War.[4] Modernistic automated cotton wool gins utilize multiple powered cleaning cylinders and saws, and offer far college productivity than their manus-powered precursors.[v]

History [edit]

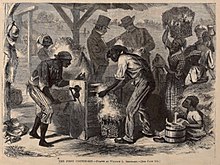

"The Kickoff Cotton Gin", an engraving from Harper's Magazine, 1869. This etching depicts a roller gin being used by enslaved Africans, which preceded Eli Whitney'south invention.[half dozen]

A unmarried-roller cotton gin came into use in India by the fifth century. An improvement invented in India was the two-roller gin, known every bit the "churka", "charki", or "wooden-worm-worked roller".[seven]

Purpose [edit]

Cotton fiber fibers are produced in the seed pods ("bolls") of the cotton wool plant where the fibers ("lint") in the bolls are tightly interwoven with seeds. To brand the fibers usable, the seeds and fibers must first be separated, a task which had been previously performed manually, with production of cotton requiring hours of labor for the separation. Many simple seed-removing devices had been invented, only until the innovation of the cotton wool gin, almost required pregnant operator attention and worked only on a small scale.[eight]

Early on cotton gins [edit]

The earliest versions of the cotton gin consisted of a single roller made of fe or wood and a flat piece of rock or woods. The earliest evidence of the cotton gin is found in the fifth century, in the form of Buddhist paintings depicting a single-roller gin in the Ajanta Caves in western Republic of india.[2] These early on gins were difficult to use and required a great deal of skill. A narrow single roller was necessary to expel the seeds from the cotton wool without crushing the seeds. The blueprint was similar to that of a mealing stone, which was used to grind grain. The early on history of the cotton gin is ambiguous, because archeologists likely mistook the cotton gin'southward parts for other tools.[two]

Medieval India [edit]

Between the 12th and 14th centuries, dual-roller gins appeared in India and Red china. The Indian version of the dual-roller gin was prevalent throughout the Mediterranean cotton trade by the 16th century. This mechanical device was, in some areas, driven past h2o ability.[9]

The worm gear roller gin, which was invented in the Indian subcontinent during the early Delhi Sultanate era of the 13th to 14th centuries, came into utilise in the Mughal Empire former around the 16th century,[x] and is still used in the Indian subcontinent through to the nowadays solar day.[2] Another innovation, the incorporation of the crank handle in the cotton gin, first appeared sometime during the belatedly Delhi Sultanate or the early Mughal Empire.[11] The incorporation of the worm gear and crank handle into the roller cotton gin led to greatly expanded Indian cotton fabric production during the Mughal era.[12]

It was reported that, with an Indian cotton gin, which is half auto and half tool, 1 man and one adult female could clean 28 pounds of cotton fiber per day. With a modified Forbes version, one homo and a boy could produce 250 pounds per solar day. If oxen were used to power sixteen of these machines, and a few people's labour was used to feed them, they could produce equally much work as 750 people did formerly.[13]

United States [edit]

The Indian roller cotton wool gin, known as the churka or charkha, was introduced to the United States in the mid-18th century, when it was adopted in the southern U.s.a.. The device was adopted for cleaning long-staple cotton, but was not suitable for the brusk-staple cotton fiber that was more common in certain states such equally Georgia. Several modifications were made to the Indian roller gin by Mr. Krebs in 1772 and Joseph Eve in 1788, merely their uses remained express to the long-staple variety, up until Eli Whitney'south development of a short-staple cotton gin in 1793.[14]

Eli Whitney's patent [edit]

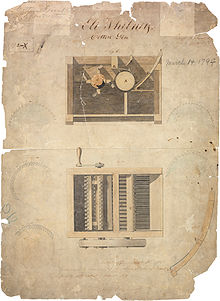

Eli Whitney's original cotton gin patent, dated March 14, 1794

Eli Whitney (1765–1825) applied for a patent of his cotton gin on October 28, 1793; the patent was granted on March fourteen, 1794, simply was non validated until 1807. Whitney'due south patent was assigned patent number 72X.[15] There is slight controversy over whether the thought of the modern cotton gin and its elective elements are correctly attributed to Eli Whitney. The popular image of Whitney inventing the cotton gin is attributed to an article on the subject written in the early on 1870s and later reprinted in 1910 in The Library of Southern Literature. In this article, the writer claimed Catharine Littlefield Greene suggested to Whitney the employ of a brush-like component instrumental in separating out the seeds and cotton. To date, Greene'southward alleged role in the invention of the gin has not been verified independently.[sixteen]

Whitney's cotton gin model was capable of cleaning 50 pounds (23 kg) of lint per day. The model consisted of a wooden cylinder covered by rows of slender wires which caught the fibers of the cotton wool assurance. Each row of wires so passed through the confined of a comb-like grid, pulling the cotton fiber fibers through the grid as they did.[17] The comb-like teeth of the grids were closely spaced, preventing the seeds, fragments of the hard dried calyx of the original cotton bloom, or sticks and other debris fastened to the fibers from passing through. A serial of brushes on a second rotating cylinder and so brushed the now-cleaned fibers loose from the wires, preventing the mechanism from jamming.

Many gimmicky inventors attempted to develop a blueprint that would process short staple cotton fiber, and Hodgen Holmes, Robert Watkins, William Longstreet, and John Murray had all been issued patents for improvements to the cotton gin by 1796.[18] However, the evidence indicates Whitney did invent the saw gin, for which he is famous. Although he spent many years in court attempting to enforce his patent against planters who fabricated unauthorized copies, a alter in patent constabulary ultimately made his claim legally enforceable – too late for him to brand much money from the device in the single year remaining before the patent expired.[xix]

McCarthy's gin [edit]

While Whitney's gin facilitated the cleaning of seeds from brusk-staple cotton wool, it damaged the fibers of extra-long staple cotton wool (Gossypium barbadense). In 1840 Fones McCarthy received a patent for a "Shine Cylinder Cotton-gin", a roller gin. McCarthy's gin was marketed for use with both brusque-staple and extra-long staple cotton, only was particularly useful for processing long-staple cotton. Afterward McCarthy'southward patent expired in 1861, McCarthy blazon gins were manufactured in U.k. and sold around the world.[20] McCarthy's gin was adopted for cleaning the Bounding main Isle variety of actress-long staple cotton wool grown in Florida, Georgia and Southward Carolina. It cleaned cotton several times faster than the older gins, and, when powered by one horse, produced 150 to 200 pounds of lint a day.[21] The McCarthy gin used a reciprocating knife to detach seed from the lint. Vibration acquired by the reciprocating motion limited the speed at which the gin could operate. In the middle of the 20th Century gins using a rotating blade replaced ones using a reciprocating bract. These descendants of the McCarthy gin are the only gins now used for extra-long staple cotton wool in the United States.[22]

Munger System Gin [edit]

The diesel fuel-powered gin in Burton, Texas is i of the oldest in the United States that still functions.

For a decade and a half after the stop of the Civil War in 1865, a number of innovative features became widely used for ginning in the United states of america. They included steam power instead of animal power, an automatic feeder to clinch that the gin stand ran smoothly, a condenser to make the clean cotton coming out of the gin easier to handle, and indoor presses so that cotton no longer had to be carried across the gin yard to exist baled.[23] So, in 1879, while he was running his father'south gin in Rutersville, Texas, Robert S. Munger invented additional organization ginning techniques. Robert and his wife, Mary Collett, later moved to Mexia, Texas, built a system gin, and obtained related patents.[24]

The Munger System Ginning Outfit (or organization gin) integrated all the ginning functioning machinery, thus assuring the cotton would period through the machines smoothly. Such system gins use air to movement cotton from auto to machine.[25] Munger's motivation for his inventions included improving employee working weather in the gin. All the same, the selling signal for nearly gin owners was the accompanying cost savings while producing cotton wool both more speedily and of higher quality.[26]

By the 1960s, many other advances had been made in ginning machinery, merely the manner in which cotton wool flowed through the gin machinery continued to exist the Munger system.[27]

Economic Historian William H. Phillips referred to the evolution of system ginning every bit "The Munger Revolution" in cotton ginning.[28] He wrote,

"The Munger innovations were the culmination of what geographer Charles S. Aiken has termed the second ginning revolution, in which the privately endemic plantation gins were replaced by large-scale public ginneries. This revolution, in turn, led to a major restructuring of the cotton wool gin manufacture, as the small, scattered gin factories and shops of the nineteenth century gave way to a dwindling number of large twentieth-century corporations designing and amalgam entire ginning operations."[29]

One of the few (and peradventure just) examples of a Munger gin left in existence is on brandish at Frogmore Plantation in Louisiana.

Furnishings in the United States [edit]

Prior to the introduction of the mechanical cotton gin, cotton fiber had required considerable labor to make clean and carve up the fibers from the seeds.[30] With Eli Whitney's gin, cotton became a tremendously assisting concern, creating many fortunes in the Antebellum South. Cities such as New Orleans, Louisiana; Mobile, Alabama; Charleston, South Carolina; and Galveston, Texas became major aircraft ports, deriving substantial economic benefit from cotton wool raised throughout the S. Additionally, the greatly expanded supply of cotton created strong demand for material machinery and improved auto designs that replaced wooden parts with metal. This led to the invention of many machine tools in the early 19th century.[1]

The invention of the cotton gin caused massive growth in the production of cotton in the United States, concentrated by and large in the Due south. Cotton wool production expanded from 750,000 bales in 1830 to 2.85 1000000 bales in 1850. As a result, the region became even more dependent on plantations that used black slave labor, with plantation agriculture becoming the largest sector of its economic system.[31] While it took a single slave about ten hours to separate a single pound of fiber from the seeds, a team of ii or 3 slaves using a cotton gin could produce effectually fifty pounds of cotton wool in just one day.[32] The number of slaves rose in concert with the increment in cotton product, increasing from effectually 700,000 in 1790 to around 3.2 1000000 in 1850.[33] The invention of the cotton gin led to an increased demands for slaves in the American Due south, reversing the economical decline that had occurred in the region during the late 18th-century.[34] The cotton fiber gin thus "transformed cotton as a ingather and the American South into the globe's first agricultural powerhouse".[35]

An 1896 advertising for the Lummus cotton gin

Because of its inadvertent effect on American slavery, and on its ensuring that the South'south economy developed in the management of plantation-based agriculture (while encouraging the growth of the textile industry elsewhere, such equally in the North), the invention of the cotton gin is frequently cited equally one of the indirect causes of the American Civil State of war.[4] [36] [37]

Modern cotton gins [edit]

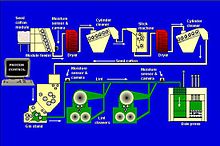

Diagram of a mod cotton gin plant, displaying numerous stages of production

In modernistic cotton product, cotton arrives at industrial cotton gins either in trailers, in compressed rectangular "modules" weighing up to 10 metric tons each or in polyethylene wrapped round modules similar to a bale of hay produced during the picking process by the nearly recent generation of cotton pickers. Trailer cotton fiber (i.east. cotton fiber not compressed into modules) arriving at the gin is sucked in via a pipe, approximately 16 inches (41 cm) in bore, that is swung over the cotton wool. This pipe is unremarkably manually operated, just is increasingly automatic in modern cotton plants. The need for trailers to haul the product to the gin has been drastically reduced since the introduction of modules. If the cotton is shipped in modules, the module feeder breaks the modules apart using spiked rollers and extracts the largest pieces of foreign material from the cotton. The module feeder's loose cotton is and then sucked into the aforementioned starting signal equally the trailer cotton.

The cotton wool and so enters a dryer, which removes excess wet. The cylinder cleaner uses six or seven rotating, spiked cylinders to break upwardly large clumps of cotton wool. Effectively foreign material, such as soil and leaves, passes through rods or screens for removal. The stick machine uses centrifugal force to remove larger foreign matter, such as sticks and burrs, while the cotton wool is held by rapidly rotating saw cylinders.

The gin stand up uses the teeth of rotating saws to pull the cotton wool through a serial of "ginning ribs", which pull the fibers from the seeds which are too big to pass through the ribs. The cleaned seed is and so removed from the gin via an auger conveyor organization. The seed is reused for planting or is sent to an oil manufactory to exist further candy into cottonseed oil and cottonseed meal. The lint cleaners again employ saws and grid bars, this time to separate immature seeds and whatever remaining foreign thing from the fibers. The bale press then compresses the cotton wool into bales for storage and shipping. Modern gins can process up to 15 tonnes (33,000 lb) of cotton wool per hr.[38]

Mod cotton gins create a substantial amount of cotton gin residue (CGR) consisting of sticks, leaves, dirt, young bolls, and cottonseed. Inquiry is currently under style to investigate the use of this waste in producing ethanol. Due to fluctuations in the chemic limerick in processing, there is difficulty in creating a consistent ethanol process, but there is potential to further maximize the utilization of waste in the cotton production.[39] [5]

See also [edit]

- Prattville Gin Factory

- Cotton bale

References [edit]

Notes

- ^ a b Roe, Joseph Wickham (1916), English and American Tool Builders, New Haven, Connecticut: Yale University Press, LCCN 16011753 . Reprinted past McGraw-Hill, New York and London, 1926 (LCCN 27-24075); and past Lindsay Publications, Inc., Bradley, Illinois, (ISBN 978-0-917914-73-7).

- ^ a b c d Lakwete, 1–half dozen.

- ^ Habib, Irfan (February 3, 2018). Economic History of Medieval Bharat, 1200-1500. Pearson Education India. ISBN9788131727911 – via Google Books.

- ^ a b Kelly, Martin. "Top Five Causes of the Ceremonious War: Leading up to Secession and the Ceremonious War". About.com. Retrieved March 14, 2011.

- ^ a b inventors.about.com; "Background on the Cotton fiber Gin", retrieved October 22, 2010.

- ^ Lakwete, 182.

- ^ "Making Cotton – The Tools of The Merchandise". Fifteeneightyfour – Bookish Perspectives from Cambridge University Printing. June 5, 2013. Retrieved September 9, 2018.

- ^ Bellis, Mary. inventors.about.com; "The Cotton wool Gin and Eli Whitney", retrieved March 12, 2012.

- ^ Baber, Zaheer (1996). The Scientific discipline of Empire: Scientific Knowledge, Civilization, and Colonial Rule in India. Albany: State Academy of New York Press. p. 57. ISBN 0-7914-2919-9.

- ^ Irfan Habib (2011), Economical History of Medieval Bharat, 1200–1500, p. 53, Pearson Education

- ^ Irfan Habib (2011), Economic History of Medieval India, 1200–1500, pp. 53–54, Pearson Education

- ^ Irfan Habib (2011), Economical History of Medieval Bharat, 1200–1500, p. 54, Pearson Education

- ^ Karl Marx (1867). Chapter xvi: "Machinery and Large-Scale Industry". Das Kapital.

- ^ Hargrett, Elizabeth; Dobbs, Chris (June six, 2017). "Cotton Gins". New Georgia Encyclopedia.

- ^ "Who Invented the Cotton Gin and How Did it Impact History?".

- ^ "Catharine Littlefield Greene, Brain Behind the Cotton fiber Gin". Finding Dulcinea. March 4, 2010. Retrieved November 6, 2013.

- ^ Harr, Grand. Eastward. (1977). Mechanics of particulate media: A probabilistic arroyo. McGraw-Hill.

- ^ Lakwete, 64–76.

- ^ The American Historical Review by Henry Eldridge Bourne, Robert Livingston Schuyler Editors: 1895 – July 1928; J.F. Jameson and others.; Oct. 1928–Apr. 1936, H.E. Bourne and others; July 1936–Apr. 1941, R.50. Schuyler and others; July 1941– G.S. Ford and others. Published 1991, American Historical Association [etc.], pp 90–101.

- ^ Lakwete, Angela. "Fones McCarthy". Encyclopedia of Alabama. Auburn Academy. Retrieved Oct xiii, 2017.

- ^ Shofner, Jerrel H.; Rogers, William Warren (April 1962). "Sea Island Cotton in Ante-Bellum Florida". The Florida Historical Quarterly. 40 (4): 378–79.

- ^ Gillum, Marvis M.; Van Doorn, D. W.; Norman, B.One thousand.; Owen, Charles (1994). "Roller Ginning". In Anthony, Stanley Westward.; Mayfield, William D. (eds.). Cotton fiber Ginner'due south Handbook. United States Department of Agronomics. p. 244. ISBN9780788124204 . Retrieved October thirteen, 2017.

- ^ Aiken, Charles S. (April 1973). "The Evolution of Cotton fiber Ginning in the Southeastern United States". Geographical Review. 63 (two): 205.

- ^ Mann, Sally (2016). Hold nonetheless : a memoir with photographs. Little, Brown and Company. pp. 314–317. ISBN 978-0-316-24775-7.

- ^ Atkinson, Edward (June 1, 1880). "Report on the Cotton Manufacturers of the United States". In Department of Interior, Census Role. Report on the Manufacturers of the United states at the 10th Census. Government Printing Office. pp. 937–984.

- ^ Mann, Sally (2016). Hold nevertheless : a memoir with photographs. Little, Brownish and Company. p. 318. ISBN 978-0-316-24775-7.

- ^ Aiken, Charles Due south. (April 1973). "The Development of Cotton Ginning in the Southeastern United States". Geographical Review. 63 (ii): 205–206.

- ^ Phillips, William (1994). "Making a Business of It: The Evolution of Southern Cotton fiber Gin Patenting, 1831-1890". Agricultural History. 68 (two): 88, 90.

- ^ Phillips, William (1994). "Making a Business of It: The Evolution of Southern Cotton Gin Patenting, 1831-1890". Agricultural History. 68 (2): 85–86.

- ^ Hamner, Christopher. teachinghistory.org, "The Disaster of Innovation", retrieved July 11, 2011.

- ^ Pierson, Parke (September 2009). "Seeds of conflict". America's Ceremonious War. 22 (4): 25.

- ^ Woods, Robert (September one, 2009). "A Turn of the Creepo Started the Civil War." Mechanical Engineering.

- ^ Smith, N. Jeremy (July 2009). "Making Cotton Male monarch". Earth Trade. 22 (7): 82.

- ^ Robert O. Woods (Dec 28, 2010). "How the Cotton fiber Gin Started the Ceremonious War". The American Society of Mechanical Engineers . Retrieved September 17, 2020.

- ^ Underhill, Paco (2008). "The cotton fiber gin, oil, robots and the store of 2020". Display & Design Ideas. twenty (10): 48.

- ^ Joe Ryan. "What Caused the American Ceremonious State of war?" AmericanCivilWar.com. Retrieved March 14, 2011.

- ^ Randy Golden, "Causes of the Civil War". Almost North Georgia. Retrieved March fourteen, 2011.

- ^ "Folio iii : USDA ARS". www.ars.usda.gov . Retrieved Nov 25, 2021.

- ^ Agblevor, Foster A.; Batz, Sandra; Trumbo, Jessica (February three, 2018). "Composition and Ethanol Production Potential of Cotton Gin Residues". Biotechnology for Fuels and Chemicals. Humana Press, Totowa, NJ. pp. 219–230. doi:10.1007/978-one-4612-0057-4_17. ISBN978-1-4612-6592-4.

Bibliography

- Lakwete, Angela (2003). Inventing the Cotton wool Gin: Machine and Myth in Antebellum America. Baltimore: The Johns Hopkins Academy Press. ISBN9780801873942.

External links [edit]

- Overview of a Cotton Gin – USDA site

- The Story of Cotton wool – National Cotton Council of America site

- National Cotton Ginners Association

- United states of america Cotton Gin Industry – EH.Net Encyclopedia of Economic History

- Invention of Cotton fiber Gin – eHistory.com

- Cotton: the cobweb of life – includes a schematic diagram illustrating the seed removal process

- Video of manual cotton fiber gin in operation via YouTube

Source: https://en.wikipedia.org/wiki/Cotton_gin

0 Response to "What Type of Goods Includes Raw Materials Used to Produce Otherã¢â‚¬â€¹ Products?"

Post a Comment